As the Batı Anadolu Group Of Companies, we continue to increase our environment and energy efficiency investments in accordance with our principles of "continuous improvement and continual development", which are indispensable for industry. Our Gaziemir and Urla Ready-Mixed Concrete Plants have received an award at the awards ceremony realized by the Turkish Ready Mixed Concrete Association in order to enable its members to make environmentally friendly production. Representing Turkey, our facilities were also granted an award by the European Ready-Mixed Concrete Association (ERMCO) as a result of the audits conducted by independent auditors.

We have planted 50 thousand saplings in about 40 hectares (400 thousand m2) within the scope of our rehabilitation works we have launched in Belkahve since 2007. We restore the ecological balance in the area of any of our limestone mines, where we have stopped mining the limestone we use in cement production, through our rehabilitation works we carry out immediately after we stop our activities at the relevant mine. By harmonizing the topography of the site that has emerged after our activities with its natural topography, we ensure that the site is available for use with agricultural purposes and for the purposes of forestry.

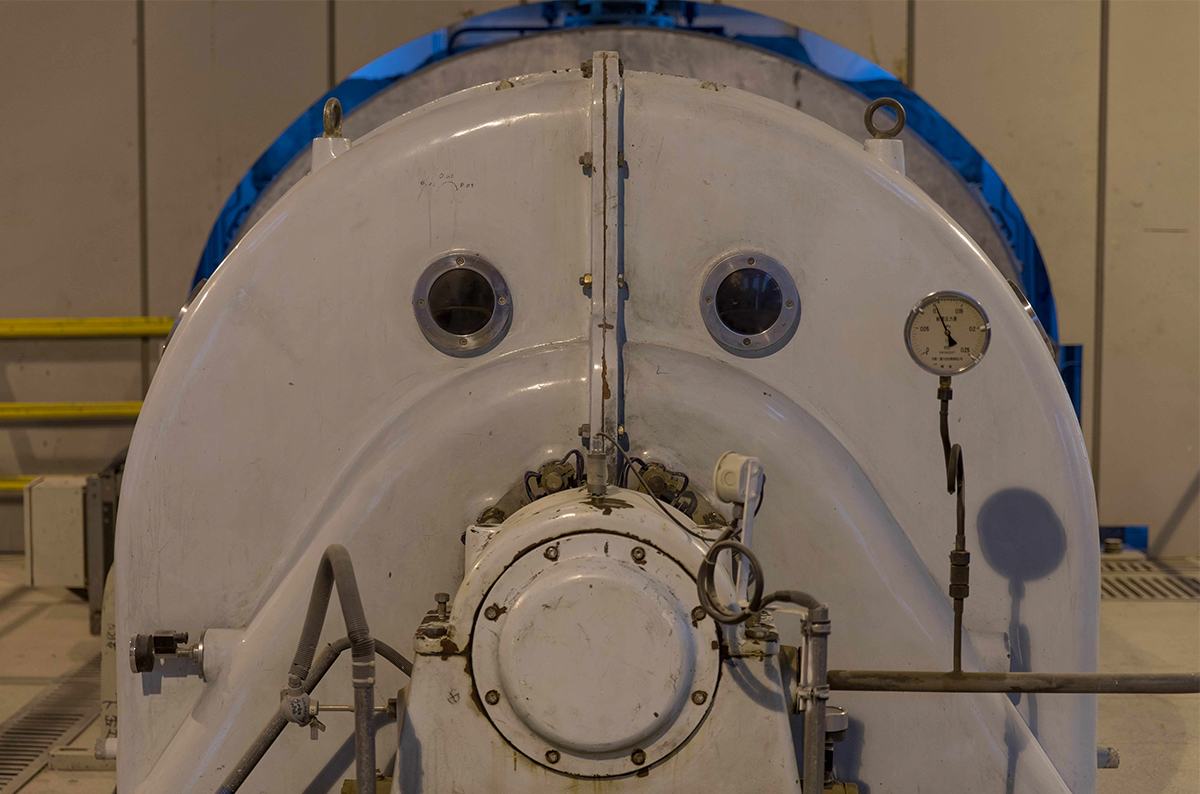

In order to generate some of the electricity we consume by utilizing the waste heat produced by our production process, we have completed our projects of "Waste Heat Electric Power Generation Plant" in our Batıçim and Batısöke cement factories. As part of our said energy efficiency projects, we are generating 30% of the electricity that we need through the electric power generation plants established in our said factories. Thus, we contribute to the environment by preventing 37,000 tonnes in carbon emissions, which correspond to the amount of oxygen provided by 59,000 trees in an entire year.

We have made an investment of 450,000 tonne-capacity inddor clinker storage area in order to prevent the dust produced during the storage of the clinkers produced in Batıçim and Batısöke, and to ensure homogenization. As the Batı Anadolu Group Of Companies, we contribute to the environment by preventing an average of 500,000 tonnes in carbon emissions annually, thanks to the investments we have made so far in the environment and energy efficiency projects.

With the development of bag filter technology, we have carried out the "Bag Filter" conversion in our factories and made significant progress in reducing the dust concentration in our Batıçim and Batısöke cement factories as a result. Thanks to these modernization works utilizing the latest technology, we have managed to reduce the amount of particulate in 1 cubic meter down to 10mg compared to the 120 mg of particulates in 1 cubic meter, which is the legally enforced upper limit value.

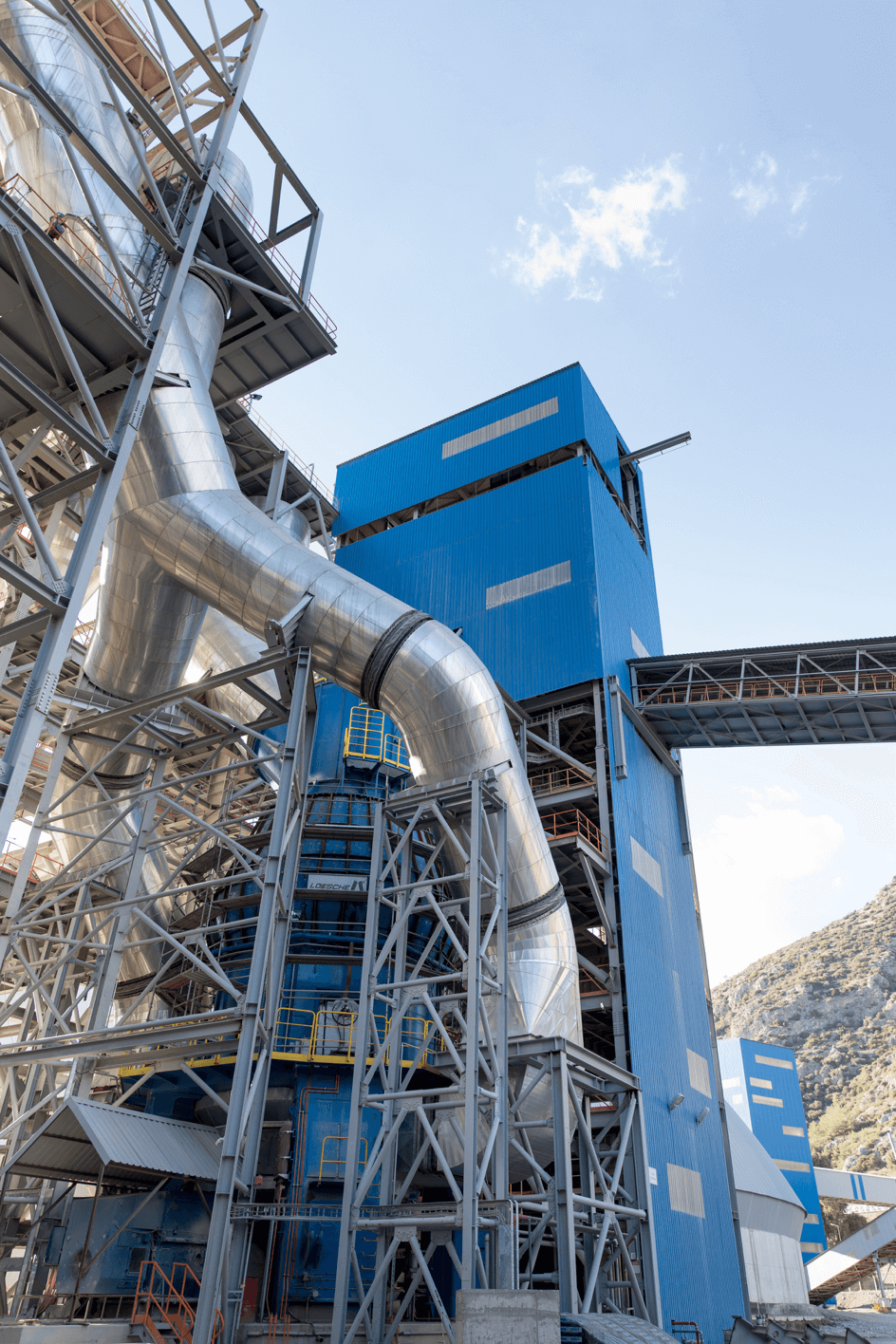

We have saved up to 19% in electrical energy used in the production of the Farin with the verticaal raw material mill, that is our energy efficiency project. We reduced our power consumption from 24 kWh per ton down to 20 kWh per ton by replacing the two existing raw material mills in Batıçim with one vertical raw material mill. In this way, we have achieved a more dust-free and clean production environment and a reduction of 8,162,000 kWh in our annual power consumption as a result of the innovation utilized technology.